2pc Camp Series Front Fixed Length End Links

Jeep Wrangler JK/JKU 07-18

| SKU: CMP-J-JK-FEL2Vehicle Fitment: Jeep Wrangler JK 07-18 – Precision-engineered for all trims to enhance suspension control, handling, and off-road capability.

About this product

Vehicle Fitment: Jeep Wrangler JK 07-18 – Precision-engineered for all trims to enhance suspension control, handling, and off-road capability.

Warranty: Lifetime warranty on all non-wear items

To buy, select your color.

$ 202.89 $ 246.70

$ 246.70

Built to order:

1–3 day build time + Shipping

Enhanced Stability and Control

Upgrade your 2007-2018 Jeep Wrangler JK with the Camp Series Front Sway Bar End Links, engineered to reduce body roll and improve overall vehicle stability. Whether you're navigating tight corners on the road or tackling rugged off-road trails, these sway bar end links provide greater control, improved handling, and a smoother ride.

What's Included

- Front Sway Bar End Links (CMP-J-JK-FEL2)

Key Features and Benefits

- Optimized suspension performance – Designed to reduce body roll and enhance vehicle handling for both on-road and off-road driving.

- Heavy-duty construction – Made from .75" OD Cold Rolled Steel, offering exceptional durability and strength over factory components.

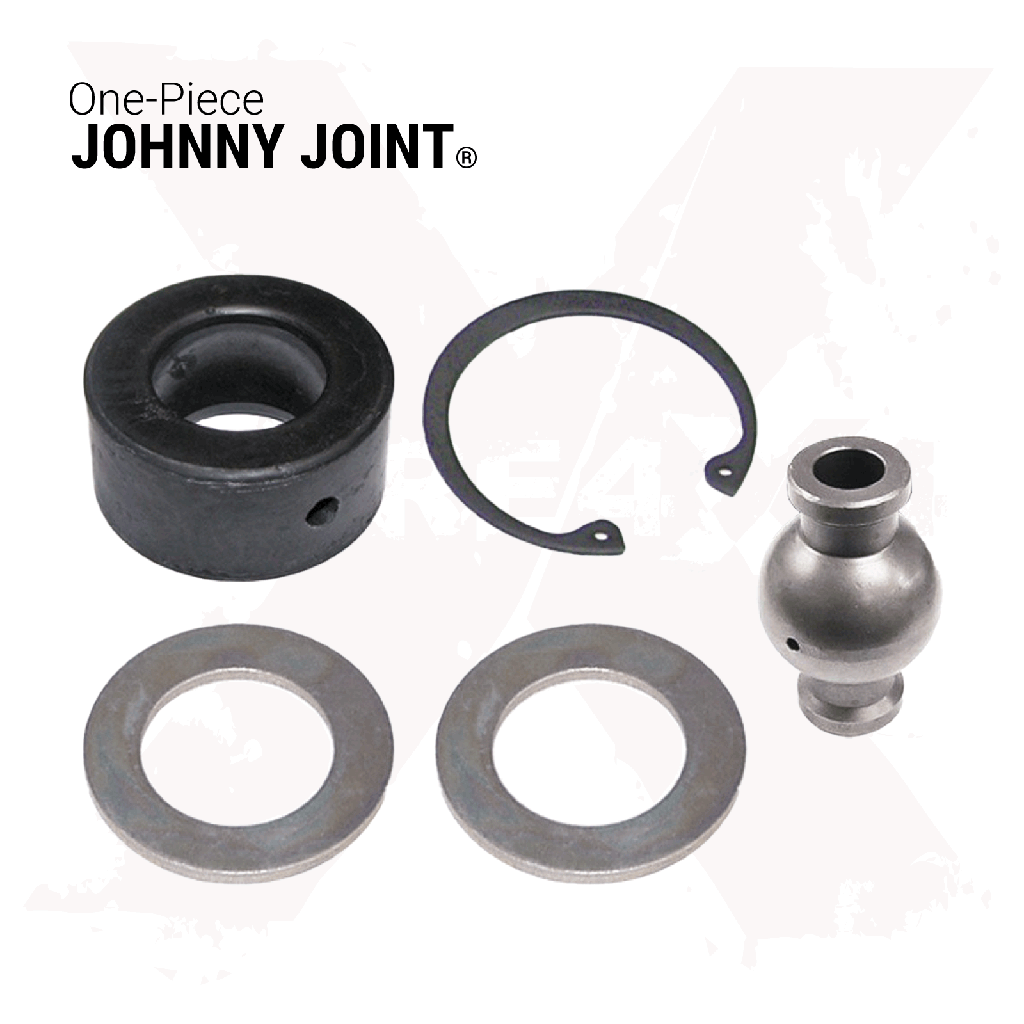

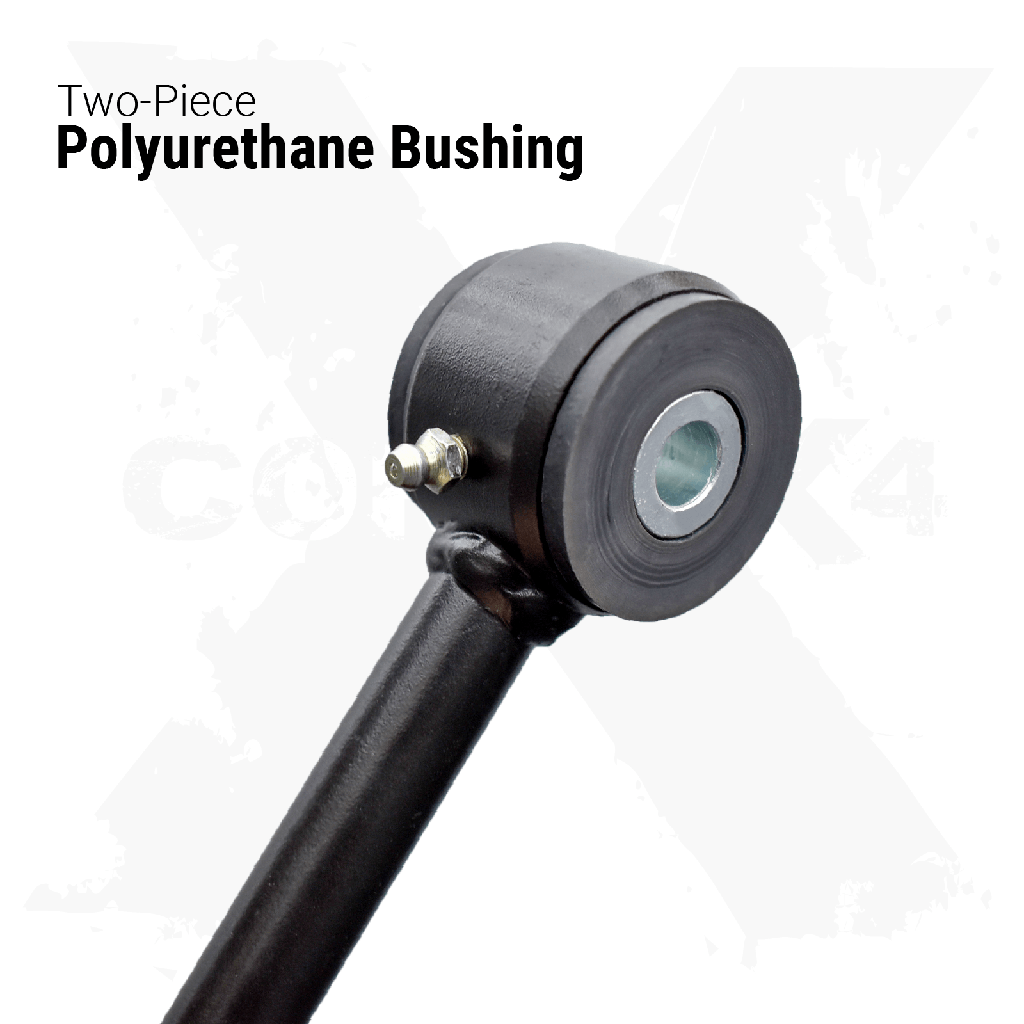

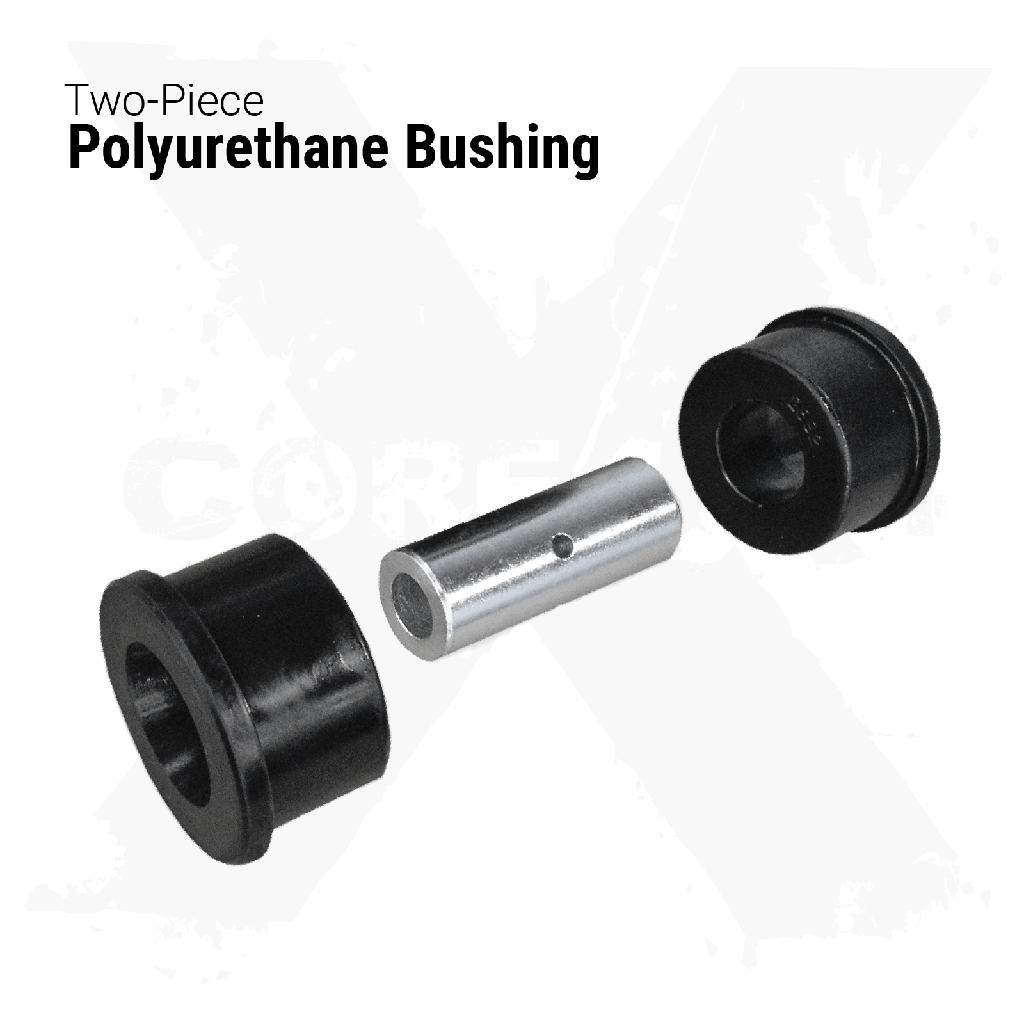

- Premium joint design – Features Johnny Joints at one end for flexibility and tapered polyurethane bushings at the other for vibration dampening, ensuring smooth and responsive operation.

- Custom fit for lifted vehicles – Built at fixed lengths tailored to match your vehicle’s lift height, providing optimal fit and function.

- Recommended pairing – For maximum suspension stability, we recommend pairing these sway bar end links with our Camp Series Rear Sway Bar End Links (CMP-J-JK-REL2).

Unrivaled Strength and Performance

Crafted from .75" OD Cold Rolled Steel, these sway bar end links are designed to withstand the toughest off-road conditions while maintaining on-road comfort. The combination of polyurethane bushings for impact absorption and Johnny Joints for articulation ensures a balanced ride quality in any driving environment.

Two-Stage Powder Coating

To ensure maximum durability and corrosion resistance, each sway bar end link undergoes a two-stage powder coating process. A zinc primer base coat provides superior rust protection, while the top coat, available in 10 colors, adds an extra layer of durability and allows you to personalize your Jeep’s look.

Made in the USA

Proudly manufactured in Orem, UT, the Camp Series Sway Bar End Links are a testament to American quality and craftsmanship. We oversee every aspect of the manufacturing process, ensuring top-tier materials and precision engineering in every product.

Optional Hardware Upgrade

Designed for simple installation using factory hardware, these sway bar end links offer a hassle-free setup. If dealing with rusted or worn bolts, we offer optional Grade 8 hardware kits, available separately, to ensure a smooth installation process.

In Conclusion

The Camp Series Front Sway Bar End Links are an essential upgrade for Jeep Wrangler JK owners looking for improved suspension stability, enhanced handling, and increased durability. Whether you're driving on highways or off-road trails, these sway bar end links provide the strength, flexibility, and performance you need. Upgrade today and experience the difference in your vehicle’s ride quality!

2pc Camp Series Front Fixed Length End Links - Key Features Include

-

Vehicle Fitment: Jeep Wrangler JK 07-18 – Precision-engineered for all trims to enhance suspension control, handling, and off-road capability.

-

CORE Advantage: Enhances handling and control by minimizing body roll, providing better on-road stability and off-road articulation.

-

Built to Length: Fixed-length design matched to your vehicle’s lift height, ensuring proper sway bar geometry for optimal suspension performance.

-

Construction: Built from .75” OD cold-rolled steel with Johnny Joints at one end and polyurethane bushings at the other for strength and flexibility.

-

Two-Stage Powder Coating: Zinc primer base and top coat available in 10 vibrant colors protect against corrosion and allow for personalized styling of your rig.

-

Warranty and Origin: Proudly manufactured in the United States, our product includes a lifetime warranty on all non-wear items, providing you with confidence and peace of mind in your purchase.

Built With

Front Links Built With .75” Cold Rolled Steel.

Welded Johnny Joints Built With one fixed end and a Polyurethane Bushing on the other fixed end.

| Make | Model | Submodel | Year |

|---|---|---|---|

|

JEEP

|

Wrangler

|

JK

|

2007

|

|

JEEP

|

Wrangler

|

JK

|

2007

|

|

JEEP

|

Wrangler

|

JK

|

2007

|

|

JEEP

|

Wrangler

|

JK

|

2007

|

|

JEEP

|

Wrangler

|

JK

|

2007

|

|

JEEP

|

Wrangler

|

JK

|

2007

|

|

JEEP

|

Wrangler

|

JK

|

2008

|

|

JEEP

|

Wrangler

|

JK

|

2008

|

|

JEEP

|

Wrangler

|

JK

|

2008

|

|

JEEP

|

Wrangler

|

JK

|

2008

|

|

JEEP

|

Wrangler

|

JK

|

2008

|

|

JEEP

|

Wrangler

|

JK

|

2008

|

|

JEEP

|

Wrangler

|

JK

|

2009

|

|

JEEP

|

Wrangler

|

JK

|

2009

|

|

JEEP

|

Wrangler

|

JK

|

2009

|

|

JEEP

|

Wrangler

|

JK

|

2009

|

|

JEEP

|

Wrangler

|

JK

|

2009

|

|

JEEP

|

Wrangler

|

JK

|

2009

|

|

JEEP

|

Wrangler

|

JK

|

2009

|

|

JEEP

|

Wrangler

|

JK

|

2010

|

|

JEEP

|

Wrangler

|

JK

|

2010

|

|

JEEP

|

Wrangler

|

JK

|

2010

|

|

JEEP

|

Wrangler

|

JK

|

2010

|

|

JEEP

|

Wrangler

|

JK

|

2010

|

|

JEEP

|

Wrangler

|

JK

|

2010

|

|

JEEP

|

Wrangler

|

JK

|

2010

|

|

JEEP

|

Wrangler

|

JK

|

2010

|

|

JEEP

|

Wrangler

|

JK

|

2010

|

|

JEEP

|

Wrangler

|

JK

|

2010

|

|

JEEP

|

Wrangler

|

JK

|

2011

|

|

JEEP

|

Wrangler

|

JK

|

2011

|

|

JEEP

|

Wrangler

|

JK

|

2011

|

|

JEEP

|

Wrangler

|

JK

|

2011

|

|

JEEP

|

Wrangler

|

JK

|

2011

|

|

JEEP

|

Wrangler

|

JK

|

2011

|

|

JEEP

|

Wrangler

|

JK

|

2011

|

|

JEEP

|

Wrangler

|

JK

|

2011

|

|

JEEP

|

Wrangler

|

JK

|

2012

|

|

JEEP

|

Wrangler

|

JK

|

2012

|

|

JEEP

|

Wrangler

|

JK

|

2012

|

|

JEEP

|

Wrangler

|

JK

|

2012

|

|

JEEP

|

Wrangler

|

JK

|

2012

|

|

JEEP

|

Wrangler

|

JK

|

2012

|

|

JEEP

|

Wrangler

|

JK

|

2013

|

|

JEEP

|

Wrangler

|

JK

|

2013

|

|

JEEP

|

Wrangler

|

JK

|

2013

|

|

JEEP

|

Wrangler

|

JK

|

2013

|

|

JEEP

|

Wrangler

|

JK

|

2013

|

|

JEEP

|

Wrangler

|

JK

|

2013

|

|

JEEP

|

Wrangler

|

JK

|

2014

|

|

JEEP

|

Wrangler

|

JK

|

2014

|

|

JEEP

|

Wrangler

|

JK

|

2014

|

|

JEEP

|

Wrangler

|

JK

|

2014

|

|

JEEP

|

Wrangler

|

JK

|

2014

|

|

JEEP

|

Wrangler

|

JK

|

2014

|

|

JEEP

|

Wrangler

|

JK

|

2015

|

|

JEEP

|

Wrangler

|

JK

|

2015

|

|

JEEP

|

Wrangler

|

JK

|

2015

|

|

JEEP

|

Wrangler

|

JK

|

2015

|

|

JEEP

|

Wrangler

|

JK

|

2015

|

|

JEEP

|

Wrangler

|

JK

|

2015

|

|

JEEP

|

Wrangler

|

JK

|

2016

|

|

JEEP

|

Wrangler

|

JK

|

2016

|

|

JEEP

|

Wrangler

|

JK

|

2016

|

|

JEEP

|

Wrangler

|

JK

|

2016

|

|

JEEP

|

Wrangler

|

JK

|

2016

|

|

JEEP

|

Wrangler

|

JK

|

2016

|

|

JEEP

|

Wrangler

|

JK

|

2016

|

|

JEEP

|

Wrangler

|

JK

|

2016

|

|

JEEP

|

Wrangler

|

JK

|

2016

|

|

JEEP

|

Wrangler

|

JK

|

2016

|

|

JEEP

|

Wrangler

|

JK

|

2017

|

|

JEEP

|

Wrangler

|

JK

|

2017

|

|

JEEP

|

Wrangler

|

JK

|

2017

|

|

JEEP

|

Wrangler

|

JK

|

2017

|

|

JEEP

|

Wrangler

|

JK

|

2017

|

|

JEEP

|

Wrangler

|

JK

|

2017

|

|

JEEP

|

Wrangler

|

JK

|

2017

|

|

JEEP

|

Wrangler

|

JK

|

2017

|

Each rebuild kit includes all necessary components to replace and restore wearable parts.

| Color | Black or Blue or Charcoal or Green or LightGreen or Orange or Purple or Red or White or Yellow |

| Lift Size | Stock Height or Lifted 1" or Lifted 2" or Lifted 3" or Lifted 4" or Lifted 5" or Lifted 6" or Lifted 7" or Lifted 8" or Custom length or 1/2 sizes (put desired length in the Order Notes) |

| Series | Camp Series |

| Brand | CORE 4X4 |

| Notes: | - |

| Placement on Vehicle | Front |

| Mounting Style | Bolt-On |

To buy, select your color.

$ 202.89 $ 246.70

$ 246.70

Built to order:

1–3 day build time + Shipping

?unique=cd10902)

?unique=cd10902)